how to make a vacuum forming machine

Lets make a part. Clamp the channel to a table edge and cut two 9 and two 1 ½long pieces of channel.

Protoform Vacuum Forming Machine Volpin Props

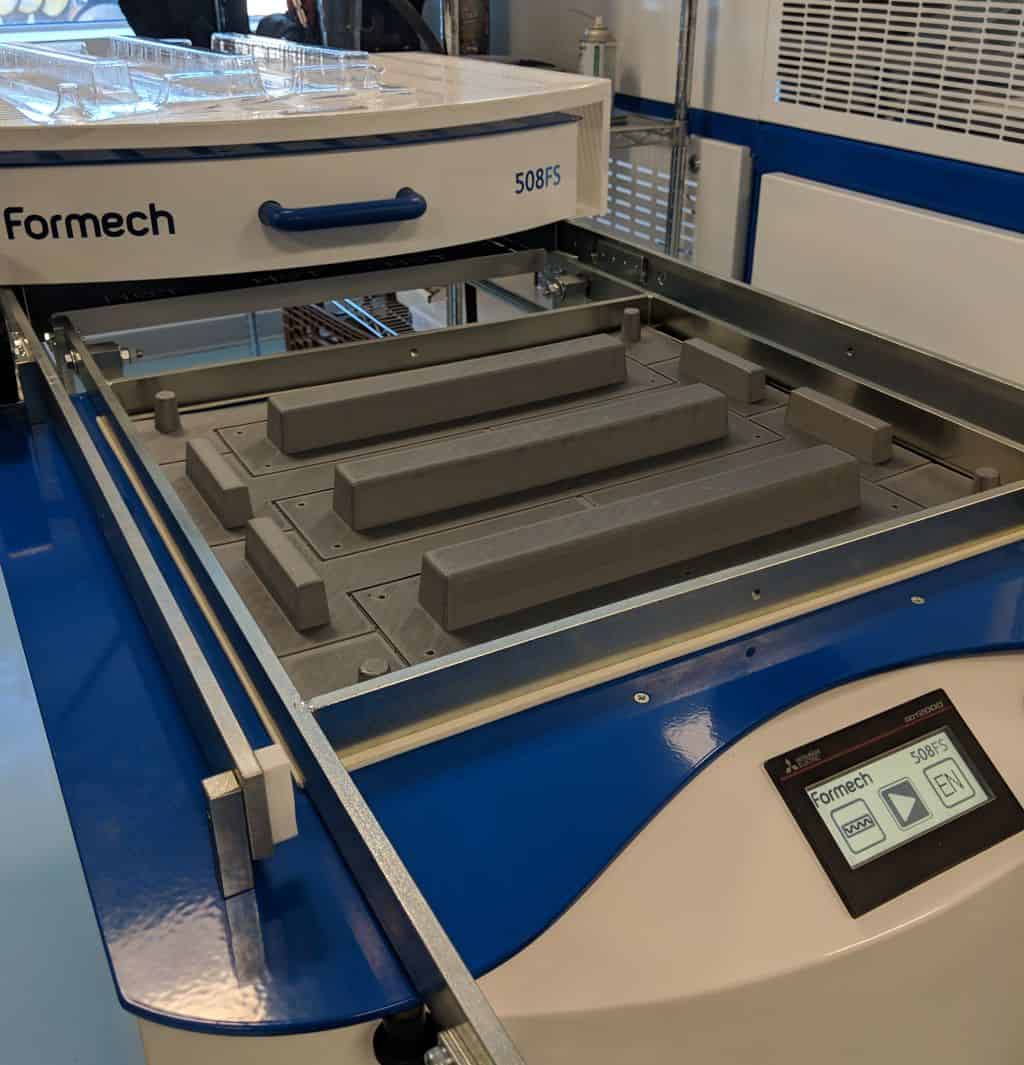

Shuttle forming machine vacuum tank After the plastic is rotated out of the heater and into the forming station the platen lifts or lowers the tool into the plastic.

. Bill shows you how to quickly make a vacuum forming machine from cheap hardware store supplies-Check out our new BIG Vacuum Form tutorial. Put the weather strip all. The heads of the screws are countersunk flush with the top of the door.

The vacuum should suck. The vacuum pump underneath then draws out the air under the sheet so that the plastic forms the shape of the object. We started with 12 x 24 inch sheets of white polystyrene plastic about 75mm thick and worked up to ¼ inch thick sheets of PET-G.

Add Tip Ask Question Comment. Place your mold anywhere on the perforated forming surface also called the. Be sure to use oven mits itll be hot.

It cools and the job is done. LOAD AND HEAT PLASTIC. The screws go right through the thin plastic and help hold it in place.

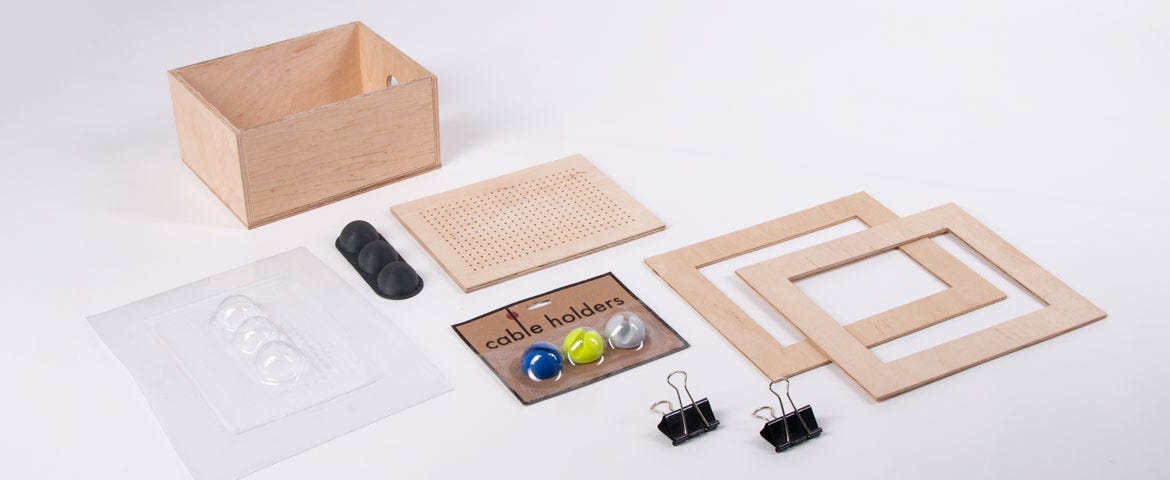

When dealing with vacuum forming machines using the industry standard pump and Tank systems make the tank large enough so that there isnt too much vacuum loss at the end of. Turn on the vacuum and quickly move the frame assembly from the oven to the vacuum table and slide it down over the part. Metal ½ square steel tubing 96 116 wall thickness lincane perforated al sheet 36x36 ¾ c-channel 116 thickness 104 length needed wood 24x48 peg board unless a smaller sheet is.

Place your mold or pattern. These will hold the plastic holder parts together in use. In this video Ill tell you all about my homebrew vacuum forming machine including the easy heating solution that I came up withHeres a follow up video on.

Releasing the mold from the plastic before it fully cools within 2-3 minutes of. Then I screw the perforated plate onto the base frame of the thermoformer and. The frame is now ready to go into the oven.

Applying a coating of silicone release spray to the mold before forming will aid in the release. Clip a plastic sheet into the carrier frame and raise the lift handle until it locks. To use the vacuum forming machine pre-heat a plastic sheet in an oven put it between the plywood and connect a vacuum cleaner to suck the air out.

Clip a plastic sheet into the pivoting clamp frame and swing it over to the oven side for heating. Now I seal all joints with acrylic so that the vacuum can become as strong as possible. This raises the plastic to the overhead oven where it will heat until it gets soft.

Zmorph Making And Assembling This Diy Vacuum Forming Machine Will Take You Less Than A Day Facebook

Vacuum Former Plans From Special Effect Supply

Vacucu3d The Best Desktop Vacuum Former Create Prototypes Molds And Casts In Office Classroom Kitchen Built In Vacuum Pump Easy To Use Realize Your Idea On Your Desk Amazon Ca Home

How To Make A Diy Vacuum Forming Machine With Zmorph Vx By Zmorph Sa Medium

How To Make A Larger Vacuum Former I Like To Make Stuff Youtube

Diy Vacuum Forming Photos Images Pictures On Alibaba

Intro To Vacuum Forming Thermoforming Mould Making

Easy Vac 2 Vacuum Forming Machine Msli Dental Supplies

Makyu Formbox Create And Make With Vacuum Forming Additive X

Secrets Of Building A Plastic Vacuum Forming Machine Vincent R Gingery 9781878087225 Textbooks Amazon Canada

Easy Vac Vacuum Forming Machine Bdsi Dental Consumables Equipment Suppliers

Amazon Com Dental Vacuum Forming Machine Laboratory Heat Molding Equipment Health Household

Wholesale Diy Manual Mini Vacuum Forming Machine For Handmade Hobby Buy Diy Vacuum Forming Machine Vacuum Forming Machine Handmade Manual Mini Vacuum Forming Machine Product On Alibaba Com

Using A Big Boy Vacuum Former Prop Agenda

Diy Vacuum Former On The Cheap Hackaday

Make A Simple Vacuum Former The Shed

Manual Plastic Vacuum Forming Machine Small Blister Vacuum Forming Machine Aliexpress

Another Diy Vacuum Former 6 Steps With Pictures Instructables